Micropatterning of Vertically aligned Carbon Nanotubes Array (2013-2019)

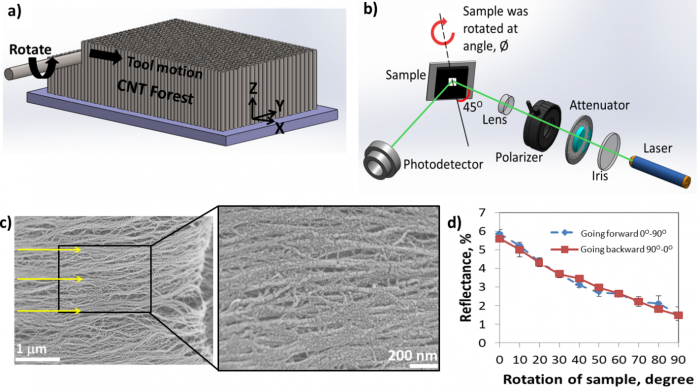

Multiwalled CNT array, also known as VACNTs/CNT forest, exhibits remarkable optical reflection when bent and flattened in bulk. This exceptional reflection from the patterned CNT surface could help to develop flexible micromirrors array. Our research investigated the mechanical bending process of the CNT forest and various optical properties of the flattened CNT surface. We found that a controlled rolling process could create an aligned and highly smooth CNT surface and exhibits anisotropic optical reflection that can be exploited to develop an angular sensor.

Funding Agency

Ministry of Higher Education Malaysia (MOHE)

Ministry of Science, Technology and Innovation Malaysia (MOSTI)

Findings (Graphical Abstract)

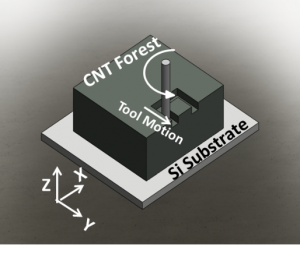

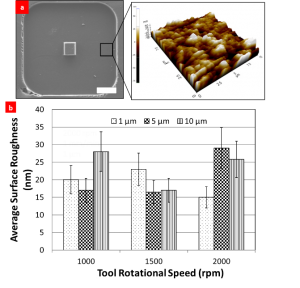

Micromechanical Bending (M2R) Process

Micromechanical Rolling (M2R) Process

Research Outputs

- An ex-situ method to convert vertically aligned carbon nanotubes array to horizontally aligned carbon nanotubes mat, Materials Research Express, Volume 6, Number 2. https://doi.org/10.1088/2053-1591/aaecc1

- Optical characterization of tip bended Vertically Aligned Carbon Nanotubes array, Chemical Physics Letters, Volume 711, November 2018, Pages 37-41, https://doi.org/10.1016/j.cplett.2018.09.011

- Optical anisotropy in micromechanically rolled carbon nanotube forest, Electronic Materials Letters volume 13, pages442–448(2017), https://doi.org/10.1007/s13391-017-6422-0

- Enhancement of reflectance of densified vertically aligned carbon nanotube forests, Carbon letters, Volume 18 / Pages.67-70 / 2016, https://doi.org/10.5714/CL.2016.18.067

- Study on micro-patterning process of vertically aligned carbon nanotubes (VACNTs), Fullerenes, Nanotubes and Carbon Nanostructures, Volume 24, 2016 – Issue 2, https://doi.org/10.1080/1536383X.2015.1119126