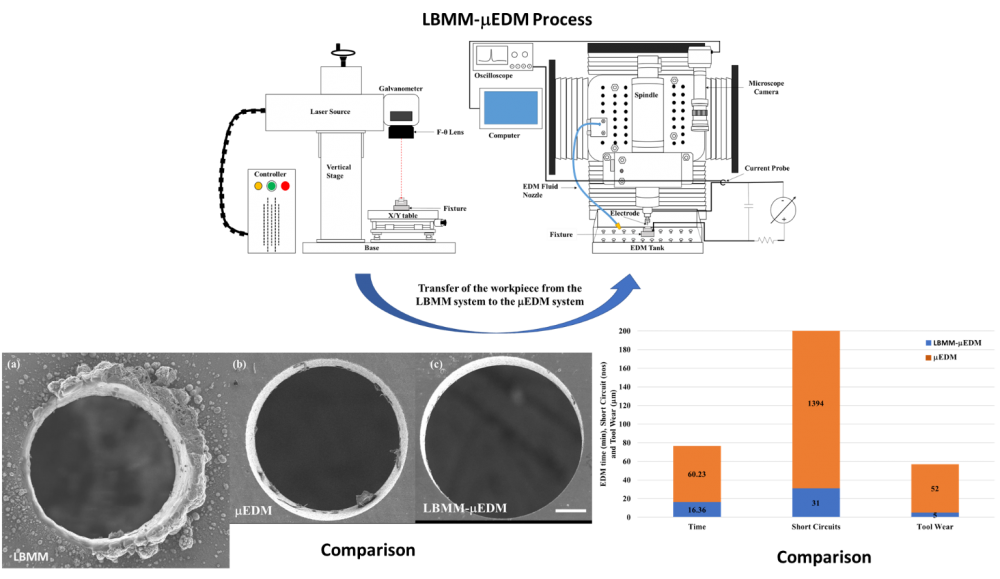

Laser-µEDM Based Sequential Micromachining (2018-)

Micromachining is a promising technology for the production of miniaturized parts. Laser micromachining is widely used for this purpose. Laser micromachining has advantages because of its high material removal rate (MRR). However, its main disadvantage is the poor machining quality due to widely spread heat affected zone (HAZ). On the other hand, micro-electro-discharge machining (microEDM) can fabricate better quality micro features due to the absence of the dominant HAZ zone. Though, this enhancement comes at the cost of very low MRR. Toward overcoming the problems associated with these two types of machining, a hybrid technique is required to integrate the advantages of LASER micromachining and microEDM. In the hybrid process, rough machining is carried out first by LASER followed by a fine operation using microEDM. This research targets to investigate LASER-microEDM based combined micromachining technique.

Funding Agency

Ministry of Higher Education Malaysia (MOHE)

Asian Office of Aerospace Research and Development

Findings (Graphical Abstract)